Products Made:

Bar Coding

Ear Tags

Keycaps

Product Traceability

Promotional Products

Laser Marking

Laser marking formulations allow for very crisp imprints on molded or extruded parts. The imprints are resistant to wear and abrasion but the permanency of the imprint is heavily dependent on the abrasion resistance of the material.

Fiber, Nd:YAG, and UV laser machines have been used with great success. The equipment speed and laser intensity must be established to ensure the greatest marking contrast color effect.

Colored laser marks exposed to UV light may fade. Incorporating UV stabilizers into the compound or applying an external UV resistant coating can slow any fading.

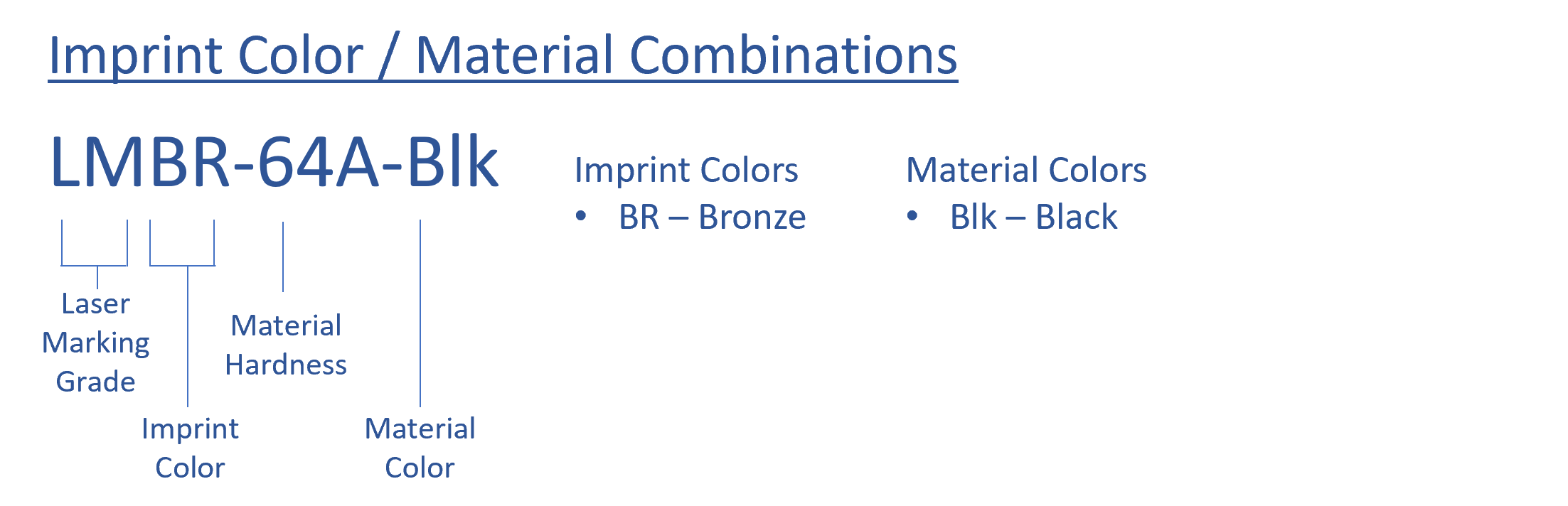

CORE Elastomers can provide compounds as natural or pre-colored with colored imprints or pre-black with traditional gray and bronze tones. CORE Elastomers can also incorporate UV stabilizers into the compound to help with UV fading for outdoor applications.